Current Location:

Introduction to Molding Technology

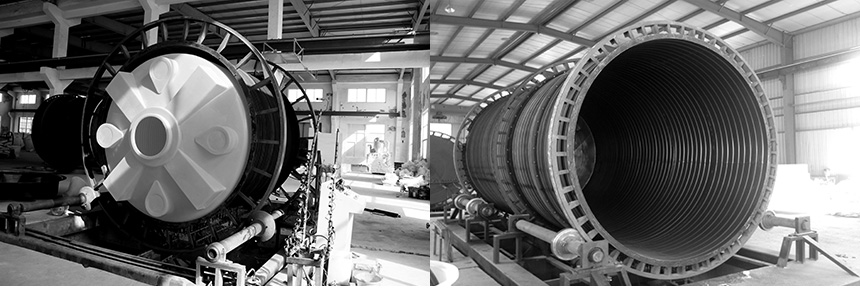

Rotational molding, also known as rotary molding, rotary casting molding, is a hollow plastic molding method. Is the first plastic raw materials added to the mold, and then along the vertical axis of the mold and continue to rotate, the mold of plastic raw materials in the role of gravity and heat, gradually evenly coated, melt adhesion to the entire surface of the cavity On the shape of the required shape, and then formed by cooling products.The characteristics of plastic technology

1. Mold cost is low: the same size of the product, the cost of rotomolding mold is about blow molding, injection mold costs 1/3 to 1/4.

2. Product edge strength is good, rotomolding can achieve the edge of the product thickness of more than 5 mm or more, completely solve the problem of thin edge of hollow products;

3. Rotational molding can be placed in a variety of inserts;

4. Molding product shape can be very complex, and the thickness of more than 5 mm;

5. Rotational molding can produce fully enclosed products;

6. Molding products can be filled with foam material, to achieve insulation.

7. No need to adjust the mold, rotomolding product thickness can be adjusted freely;

8. The product is hollow, but can adjust the wall thickness, so that the product has high strength;

9. Can provide a variety of surface pattern processing, generate a variety of color products, can be used for anti-UV anti-aging treatment, for a variety of stone, wood simulation results.Application scope

At present, rotomoulding products can be used in safety facilities, entertainment industry, river route dredging, construction, water treatment, pharmaceutical food, electronics, chemicals, aquaculture, textile printing and dyeing industries.

1. Water platform construction: mainly for the construction of maritime piers and other water platform to provide accessories, the product has a major floating dock as a plastic pontoon, a solid platform with a pile of plastic tip pile cap, and the platform corner of the anti-collision Angle etc.

2. Containers Plastic parts: widely used in storage and supply boxes, storage tanks, all kinds of industrial chemicals storage and transportation containers, such as acid, alkali, salt, chemical fertilizers, pesticide storage tanks, chemical enterprises, industrial coating Equipment, the production of rare earth in the washing tank, reaction tank, turnover me, empty boxes, litter, septic tanks, living water tanks etc.

3. The use of rotomoulding parts: mainly the use of polyethylene and PVC paste resin, rotomolding a variety of automotive parts, such as air-conditioning elbow, vortex tube, backrest, armrest, fuel tank, fender, And fuel tank, battery case, snowmobile and motorcycle fuel tank, aircraft tank, yacht and its water tanks, boats and ships and dock between the buffer absorber etc.

4. Sports equipment, toys, handicrafts Rotational molding parts: mainly PVC paste rotary molding of various parts, such as water polo, float, a small swimming pool, entertainment boats and their water tanks, bicycle cushions, Pallet, surfboard, etc. Toys such as ponies, dolls, toy boxes, fashion model models, crafts etc.

5. All kinds of large or non-standard rotomoulding parts: Shelf, machine shell, protective cover, lampshade, agricultural sprayer, furniture, canoe, camping vehicle roof, sports field device, planter, bathroom, toilet, , Advertising display cards, chairs, road isolation pier, traffic cone, river buoy, crash bucket and construction barrier.

Go Home

Go Home Chat online

Chat online Call me

Call me